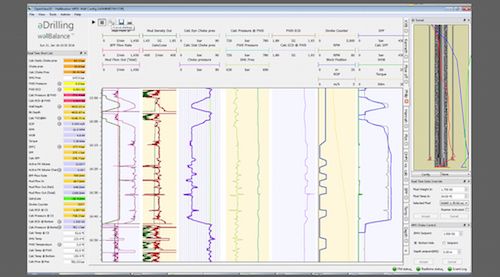

wellBalance™ improves any MPD control system to better keep a constant bottom hole pressure during MPD-operations and perform planning with an offline model. wellBalance™ provides real-time set points to the MPD control system, based on dynamic real-time simulation, calibrated against downhole measurements. It is complemented with an offline simulation tool, wellBalance™ Offline, to test and analyze operations and procedures. It is implemented by embedding a real time dynamic model into the 3rd party control system with input from the rig operation, to continuously update the ECD and temperature profile in the well.

WELLBALANCE™ OFFLINE The real time tool is derived from a more comprehensive offline tool (wellBalance™ Offline) that can be used for planning of operations. One wellBalance™ Offline license comes with each wellBalance™ license. wellBalance™ Offline license can be added. wellBalance™ Offline adds the following features, among others:

- Dynamic two-phase transport of fluids up the annulus

- Batch simulation of long pre-defined sequences, e.g. complete section plans

- Can be run on separate computer or on “real-time” computer system

- Reports from simulations will be on same format as the real time system

- Integrated tool with real-time and simulation capabilities

SUPPORTED OPERATIONS

- Circulation at different pump rates, with and without rotation.

- Static periods

- Drilling

- Reaming

- Tripping in and out

- Handles connections with or without backpressure pump

- Displacements with different fluids or one fluid with different densities

MODELS

- Dynamic mass transport: changes in boundary conditions and temperature profile will propagate through the system rather than jumping straight to a new state.

- Pressure and temperature dependent density. For the actual mud used, calculations are based on laboratory measurements

- Pressure and temperature dependent rheology. Generic laboratory data are adjusted automatically to match rig measurements done during operations, and interpolated to calculated pressure and temperature in each grid cell along the flow trajectory

- Frictional pressure loss is calculated based on fitting a three-parameter rheology model to rheology, and using published methods for handling laminar, transitional, and turbulent flow.

- Cuttings load is taken into account

- Surge & Swab

- Rotation is taken into account when calculating frictional pressure loss and heat transfer.

- Multiple fluids are tracked through the system, and calculated pressures will change gradually depending on details of rheology, density, inner and outer diameters, angle of inclination, and operational parameters

- A 2D detailed dynamic temperature model is seamlessly integrated with the 1D dynam&a

Don't Miss Out! Get the Best Deal on this Software - Email Us Now!