CemCADE

A successful cement job results in complete zonal isolation while saving time and money. To achieve this, various factors such as well security, good centralization, efficient mud removal, and gas migra- tion control must be taken into account. Temperature must be accurately predicted to properly design the fluid and eliminate excessive waiting on cement. In addition, a postjob analysis is necessary to ascertain zonal isolation and avoid any unnecessary remedial work.

The Schlumberger CemCADE* cementing design and evaluation software is integrated to help the user de- sign and optimize various cementing job parameters.

Competent Cement job design and simulation

Schlumberger engineers use CemCADE software to design, simulate, and optimize primary and plug cementing jobs. CemCADE software can design all primary land or offshore cementing operations, from large-diameter surface casing to the deepest liners.

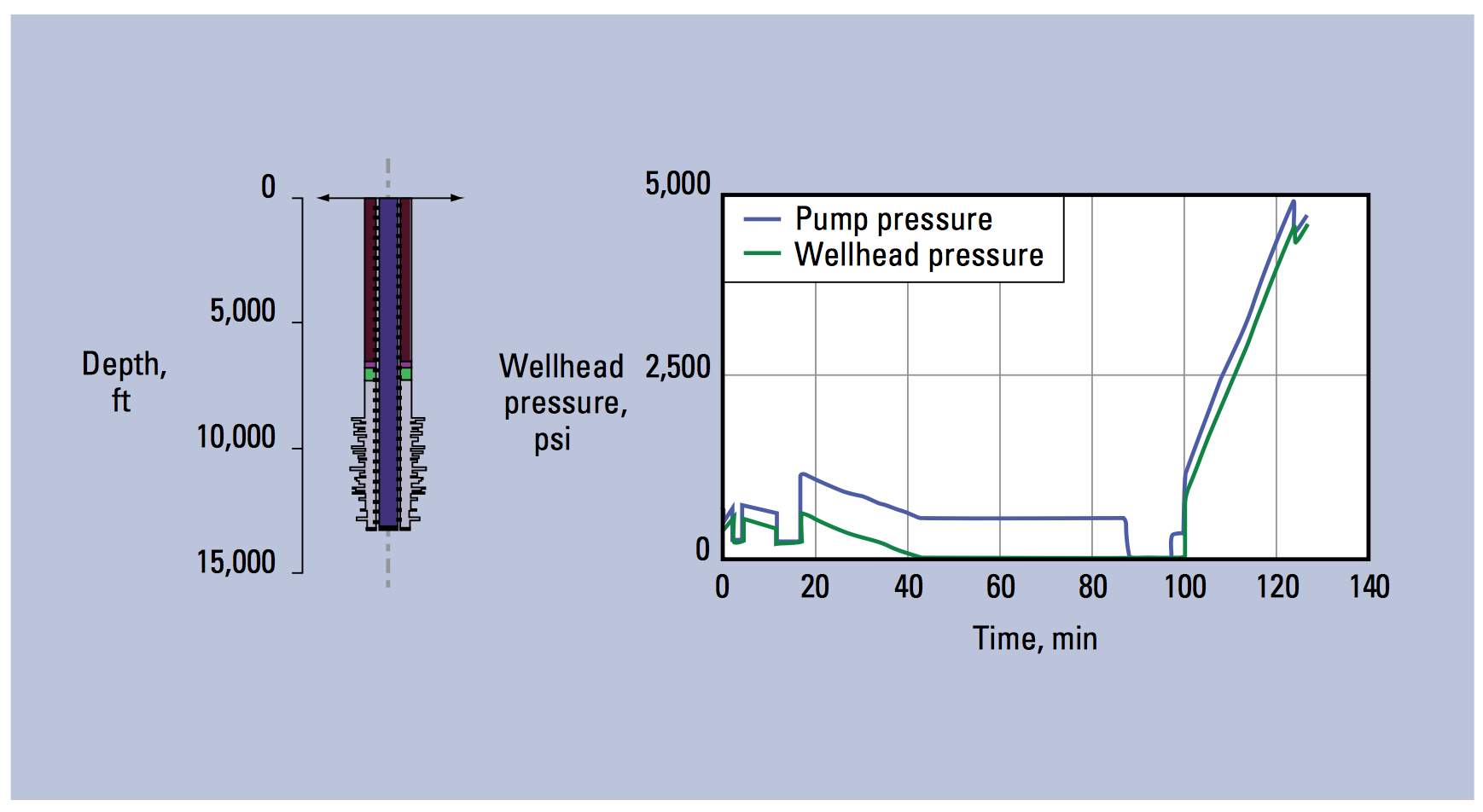

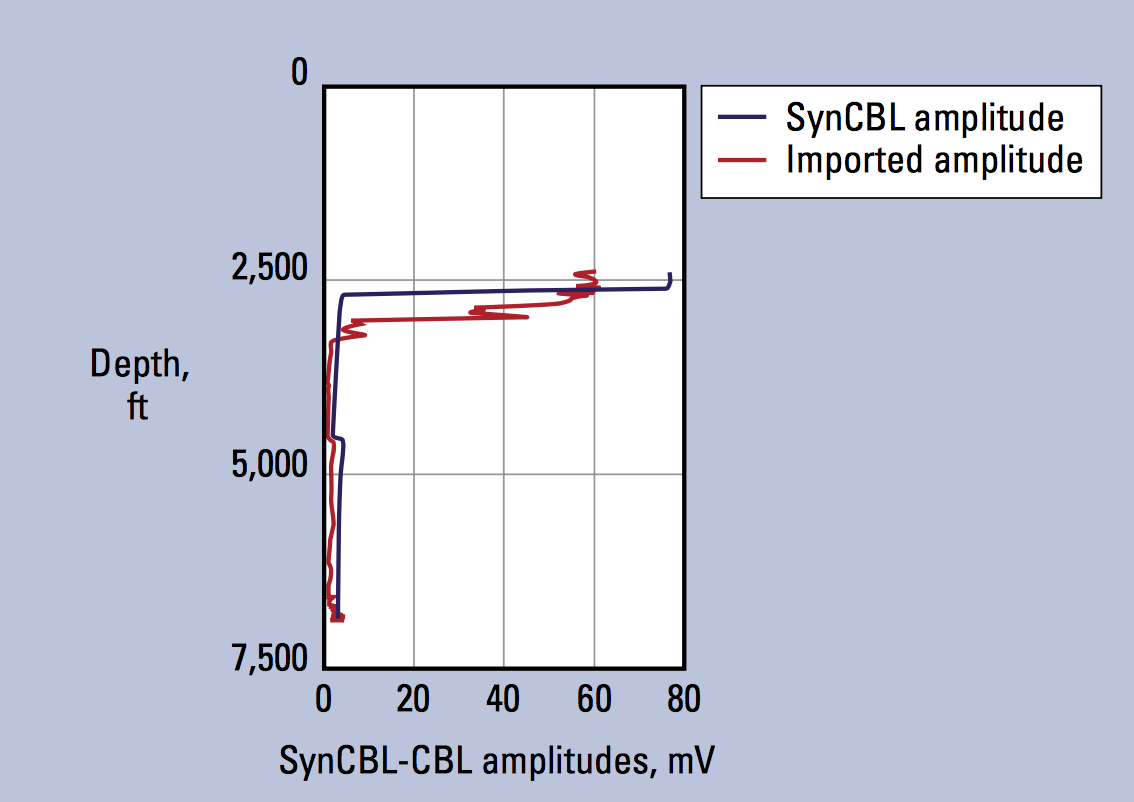

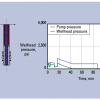

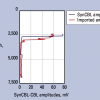

CemCADE software ensures well security at all times during the cementing job. The application optimizes pipe standoff and helps to calculate an optimum dis- placement of mud and preflushes (mud removal and cement placement) to reduce the risks of channeling and microannulus (zonal isolation). A field-validated temperature simulator predicts downhole tempera- tures, and fluid properties can be designed based on the predicted temperatures. The SynCBL module can be used to predict CBL response based on the fluid placement.

Actual job execution data can be imported into CemCADE software to compare design with actual results to verify the success of the operation. SynCBL can also be used to simulate the CBL response based on execution job data. This response is com- pared with the actual CBL data, and interpretation of the cement logs is performed.

Plug placement can be optimized using CemCADE software. The CemCADE plug placement module can predict and minimize fluid interface movement, thus reducing slurry contamination. This ability increases the success rates of cement plugs.