Drilling & Completion Software

Drilling & Completion Engineers in oil and gas industry are responsible to drill a well and making a well ready for production and injection. This basically means once drilling is finished, downhole equipments (e.g., casing, cementing, perforating, gravel packing, linear, valves, production string) need to be installed. Perforating and stimulating production/injection well is also part of completion process.

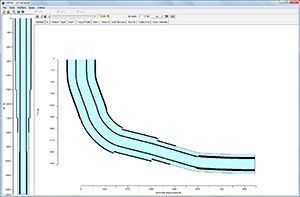

Casing strings are an indispensable asset to prevent the borehole from caving in, protect water sands from contamination, and control pressure in the well. They also serve as a path for production tubing, making it essential to determine a suitable casing string that can resist all potential loads w ...

Read More ...

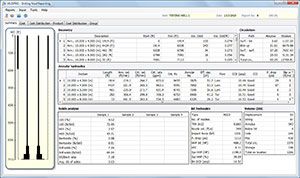

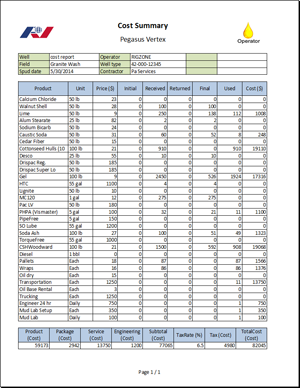

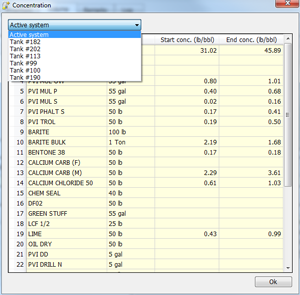

Drilling fluids are a vital part of drilling operations. It controls wellbore pressure, lubricates and cools the drill bit, carries the drill cuttings, and other essential functions. To fulfill these tasks, carefully chosen additives are incorporated into the mud to control its properties. It is the ...

Read More ...

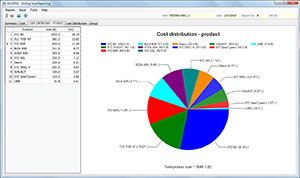

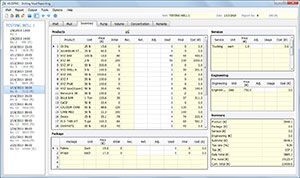

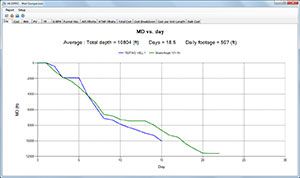

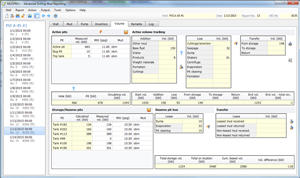

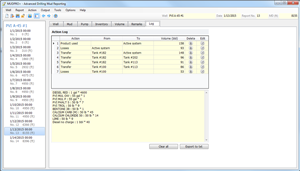

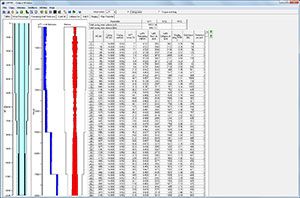

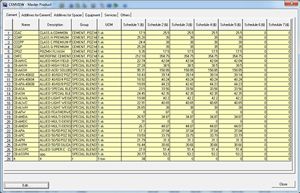

MUDPRO+, an advanced version of MUDPRO, records all actions mud engineers perform on mud, including additions, losses, returns and transitions. MUDPRO+ also keeps track of mud volumes on a daily basis. This software calculates the concentration of all additives during the drilling cycle and comes wi ...

Read More ...

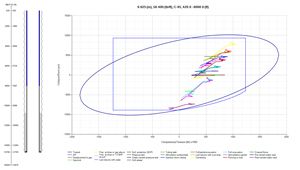

Casing wear during drilling and workover is an on-going concern. It will continue to have an impact on both well path and operation designs because it can cause catastrophic incidents such as oil spills, blowouts or even the loss of a well. PVI has conducted studies on casing wear from both an exper ...

Read More ...

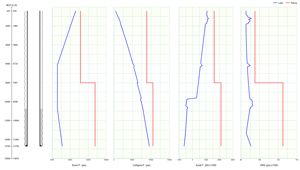

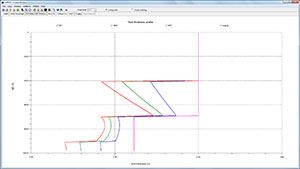

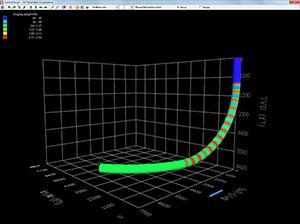

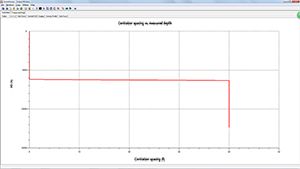

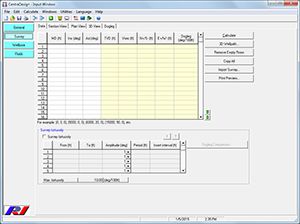

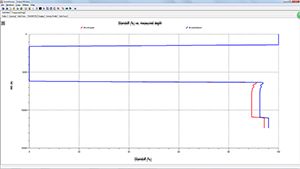

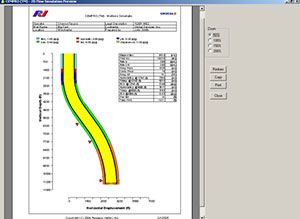

Casing centralization is one of the key elements to ensure the quality of a cementing job. It does so by preventing mud channeling and poor zonal isolation. While centralizers are used extensively, well problems continue to arise due to poor cementing jobs. The challenge that both operators and serv ...

Read More ...

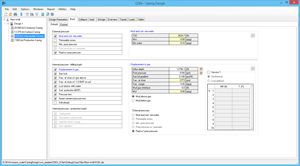

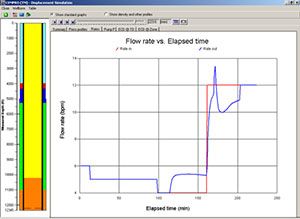

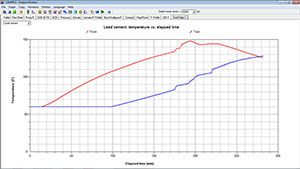

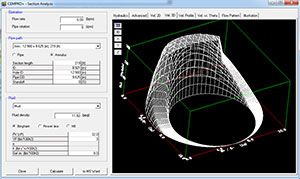

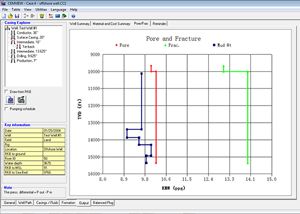

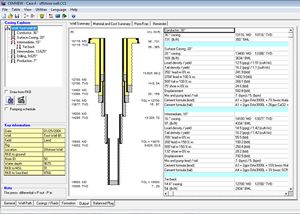

A successful cement job is one of the most important factors for of any well. There are many challenges involving increased reservoir depth, downhole temperature and pressure. Achieving wellbore integrity is more complicated than ever before. To overcome these challenges, PVI developed CEMPRO, an in ...

Read More ...

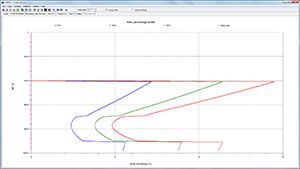

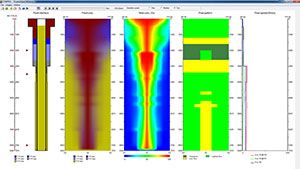

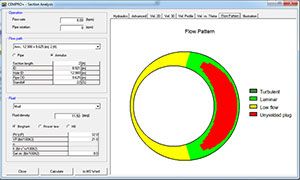

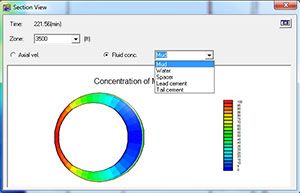

The ultimate yet most difficult goal of cementing operations is to provide zonal isolation by displacing drilling mud with cement slurries. Incomplete mud removal creates a poor cement seal and non-productive time (NPT). To ensure critical zonal isolation with mud removal optimization, PVI has devel ...

Read More ...

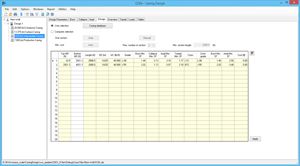

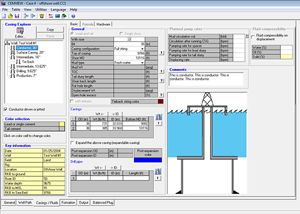

Cementing operation success or failure can potentially make or break the financial viability of a well or project. It is vital to correctly perform calculations and prevent mistakes during the design stage of a cementing job. As new technology evolves, the calculations of various parameters for ceme ...

Read More ...

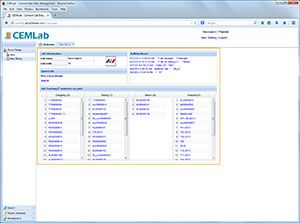

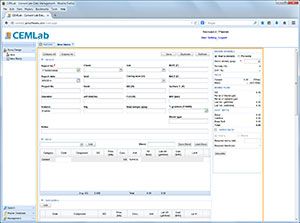

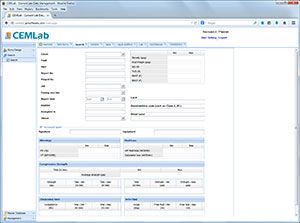

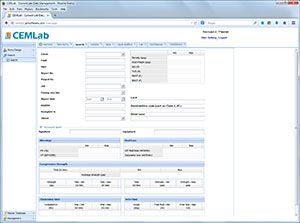

CEMLab aids experts and technicians in creating globally consistent slurry formulations and in rapidly disseminating cementing techniques. It standardizes the slurry design and provides a common historical support base for multiple cement labs worldwide. Slurry design and testing are integral parts ...

Read More ...

PVI is currently developing PlugPRO, a cement plug placement model that calculates under-displacement volumes and optimizes fluid volumes to balance slurry and spacer levels after pull out of the hole (POOH). In addition, PlugPRO also models the displacement hydraulics of fluids. We look forward to ...

Read More ...