Drilling & Completion Software

Drilling & Completion Engineers in oil and gas industry are responsible to drill a well and making a well ready for production and injection. This basically means once drilling is finished, downhole equipments (e.g., casing, cementing, perforating, gravel packing, linear, valves, production string) need to be installed. Perforating and stimulating production/injection well is also part of completion process.

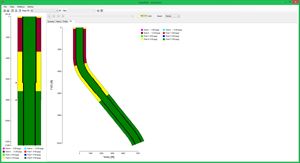

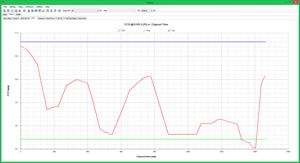

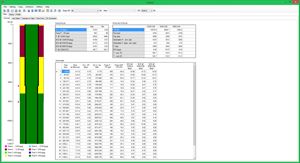

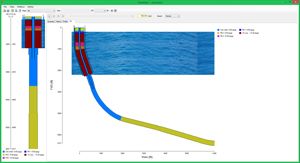

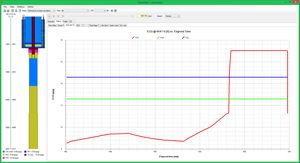

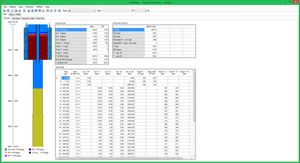

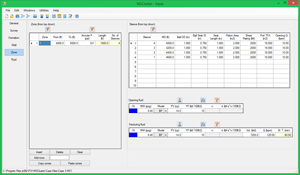

The first step to ensure an optimum completion is to remove leftover drilling fluid residue and casing debris. This requires that the drilling mud be changed out with solids-free completion fluids. Completion fluid displacement involves multiple fluids sequenced in circulation. Varying flow rates, f ...

Read More ...

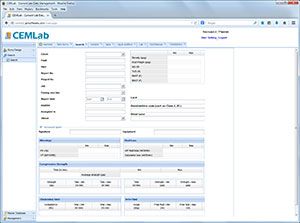

Cement is fundamental in maintaining integrity throughout the life of the well. Even if the slurry has been properly placed, changes in downhole conditions can induce thermal and mechanical cycling stresses to harm the integrity of the cement sheath. PVI is developing CEMLife, a software package tha ...

Read More ...

A successful wellbore cleanup is one of the most critical steps to ensure a trouble-free completion. Cleanup operations reduce the risk of formation damage and enhance well productivity by efficiently and meticulously planning out the removal of leftover drilling fluid residue and casing debris. In ...

Read More ...

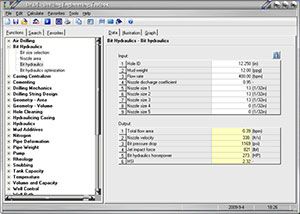

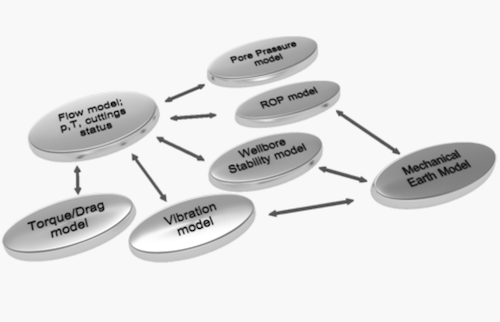

This past century has been the most pivotal in drilling technology advances with the most influential drilling professionals collaborating with literature, books, and computer programs. Despite these developments, the amount of information we are receiving can many times be overwhelming. Much of the ...

Read More ...

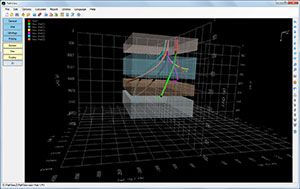

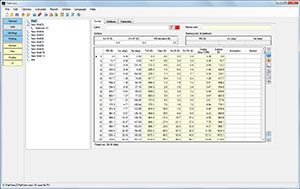

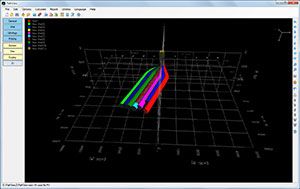

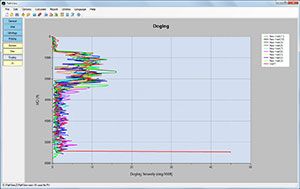

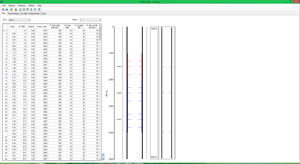

A three-dimensional visualization of a wellbore trajectory is challenging, especially for multiple and multi-lateral wells. Calculating true vertical depth (TVD), dogleg severities, and the ability to see the well path in a 3D work space is important to avoid unforeseeable issues. These features hel ...

Read More ...

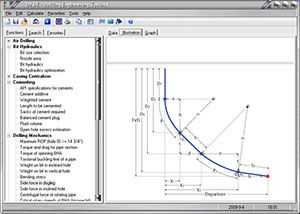

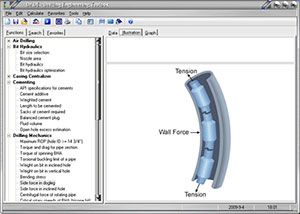

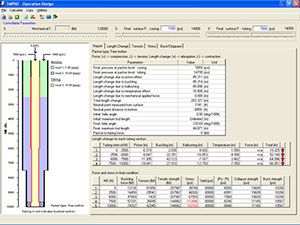

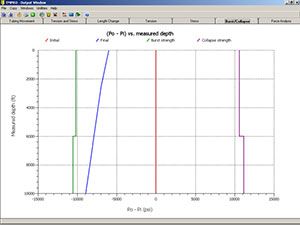

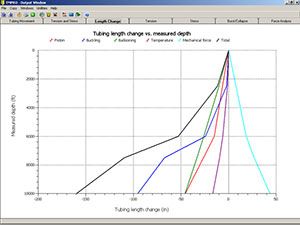

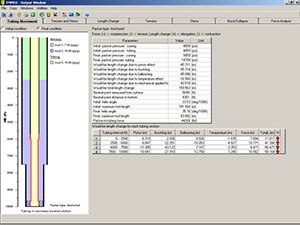

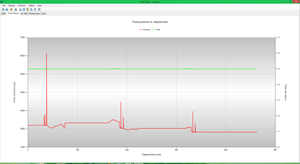

Most wells are completed and treated through a tubing and packer system. Changes in temperature and pressure inside or outside the tubing will either cause tubing length change (free motion condition), or induce force in the tubing and on the packer (limited motion or anchored condition). In deep we ...

Read More ...

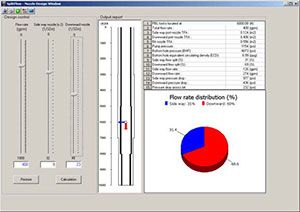

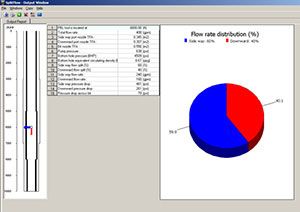

A circulation sub or bypass system can assist an operation in reducing drilling costs associated with different types of hole conditions. Originally developed to enable the aggressive pumping of LCM materials, these types of tools have evolved to benefit many applications in drilling, completion, an ...

Read More ...

Hydraulic fracturing is a very common technique in wells for shale gas, tight gas, tight oil, coal seam gas and hard rock wells. There has been an increasing trend towards multiple hydraulic fracturing as production declines. This well stimulation is usually conducted once in the life of the well an ...

Read More ...

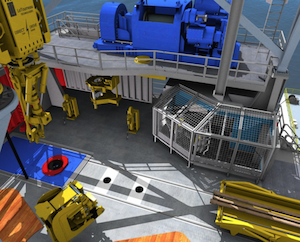

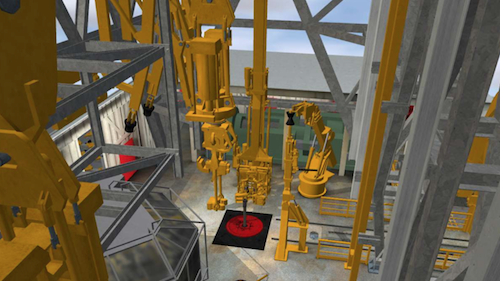

Unique functionality Our full sized hiDRILL simulator delivers unique functionality for drilling training. Offering fully equipped cyber chairs, emulated control systems and a full topside and downhole solution, hiDRILL can be delivered with different high-quality visual systems, based upon your req ...

Read More ...

The industry standard Oiltec Solutions has delivered advanced topside drilling simulators for the last two decades. In partnership with SINTEF and eDrilling, we now can offer the first “From the Derrick to the Drill bit” drilling simulator system to our clients. The hiDRILL wellSIM simulator (former ...

Read More ...