gliu@pvisoftware.com

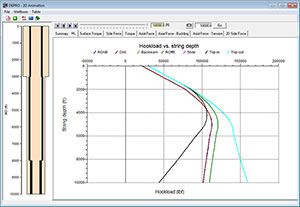

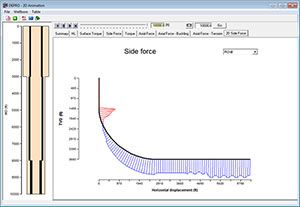

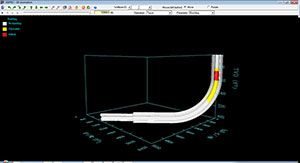

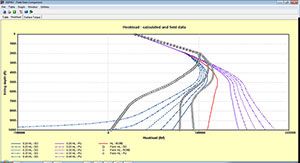

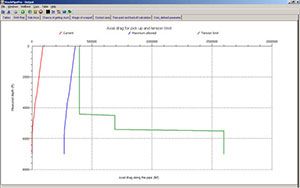

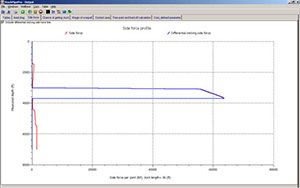

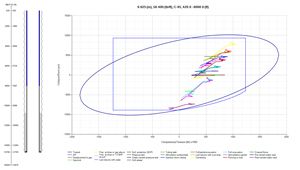

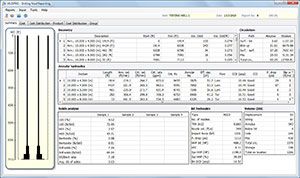

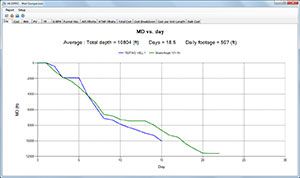

The prevalence of extended-reach directional wells today means that pipes are exposed to greater amounts of torque and drag (T&D). If the torque and drag are not evaluated, it can result in stuck pipe, pipe failures, and costly fishing jobs. With the number of extended-reach wells increasing, to ...

Read More ...

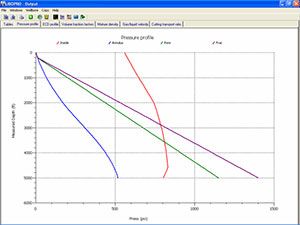

Whether you are drilling a vertical or extended-reach well, an equivalent circulating density (ECD) that is too low or too high can cause serious drilling problems or compromise your project’s budget. A successful drilling operation relies heavily on achieving an optimal ECD. Accurate modeling and o ...

Read More ...

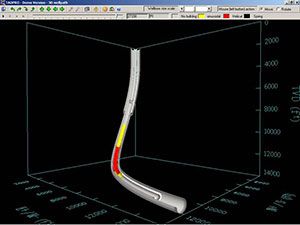

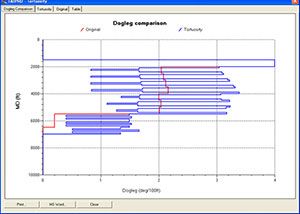

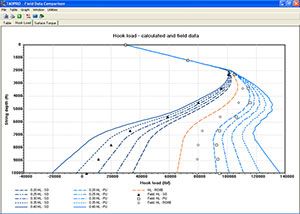

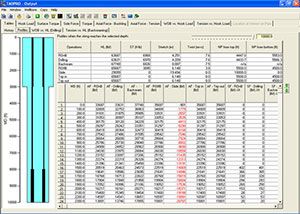

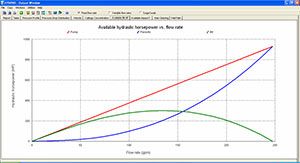

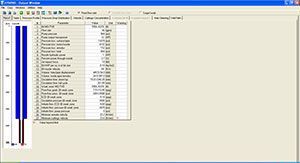

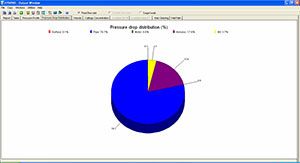

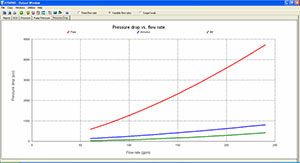

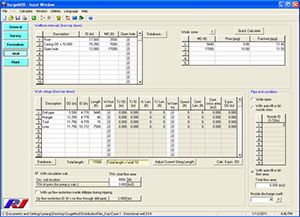

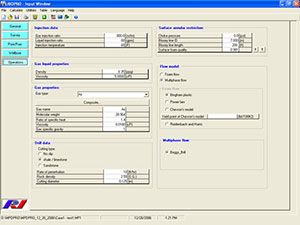

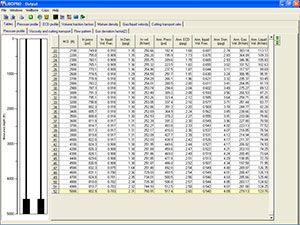

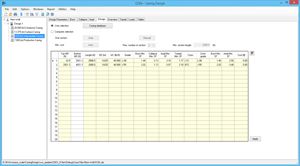

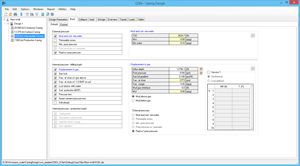

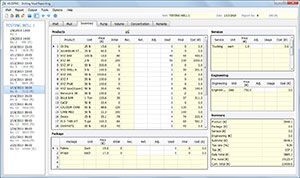

DEPRO is a comprehensive torque, drag and hydraulics program. Using this software, users can reduce many of the risks encountered in drilling and completion operations. DEPRO predicts the limits in the length of a horizontal well based on specific friction factors, recommends rig specifications, and ...

Read More ...

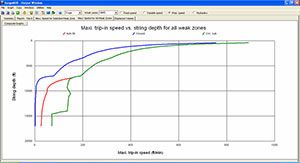

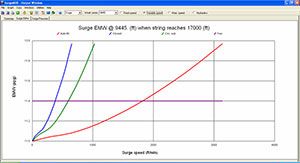

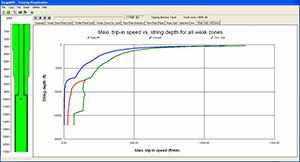

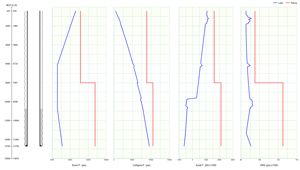

Moving a pipe in a well is accompanied by a mud displacement in the hole. This leads to pressure variations. The accurate prediction of surge and swab pressures is very important in wells where the pressure must be maintained within narrow limits to ensure trouble-free drilling and completion operat ...

Read More ...

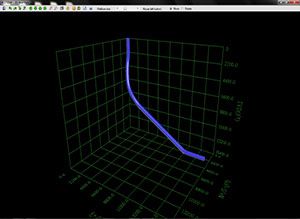

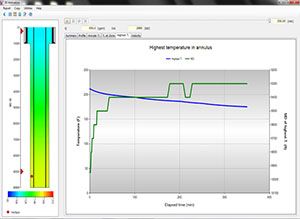

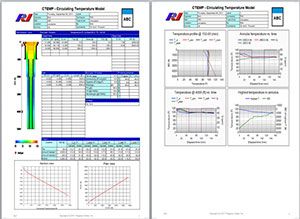

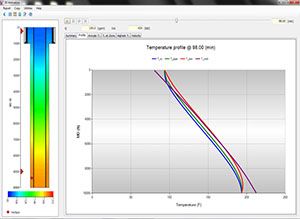

As the search for petroleum resources become more extreme in terms of depth, pressure, and temperature (HPHT drilling), wellbore circulating temperature prediction becomes a very crucial process. It has implications for flow assurance (wax, hydrates, and viscosity), stress analysis, drilling tool te ...

Read More ...

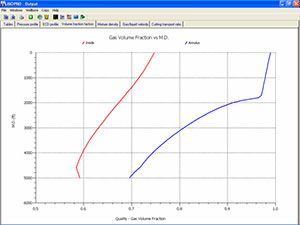

Managed Pressure Drilling (MPD), including Underbalanced Drilling (UBD) technology, precisely controls the annular fluid pressure profile within a wellbore, which allows drilling of what might otherwise be economically unattainable prospects. Managed pressure drilling is often performed with the pri ...

Read More ...

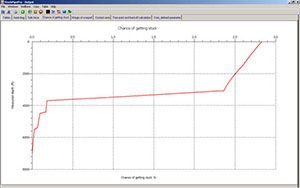

A stuck pipe can result from a wide variety of causes. Typically, these causes are related to mechanical sticking and differential sticking. Mechanical sticking can be caused by key seating, under gauge holes, wellbore instability, poor hole cleaning and related causes. Differential sticking typical ...

Read More ...

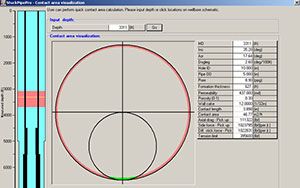

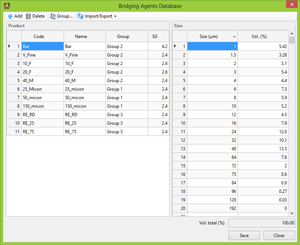

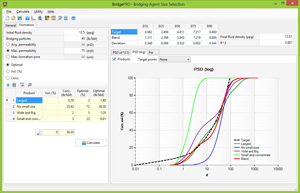

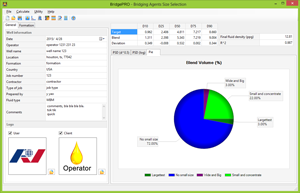

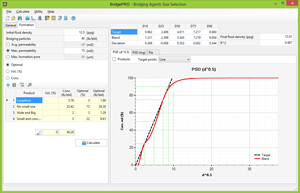

Protecting the pay zone from damage is critical to realize the full potential of any well. Reservoir drill-in fluids (RDF) are designed to prevent formation damage due to fluid invasion and solids plugging. A poorly designed RDF may react with the formation fluid creating blockage or restriction for ...

Read More ...

Casing strings are an indispensable asset to prevent the borehole from caving in, protect water sands from contamination, and control pressure in the well. They also serve as a path for production tubing, making it essential to determine a suitable casing string that can resist all potential loads w ...

Read More ...

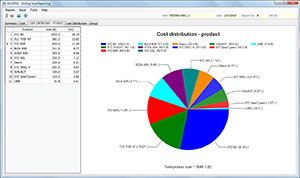

Drilling fluids are a vital part of drilling operations. It controls wellbore pressure, lubricates and cools the drill bit, carries the drill cuttings, and other essential functions. To fulfill these tasks, carefully chosen additives are incorporated into the mud to control its properties. It is the ...

Read More ...