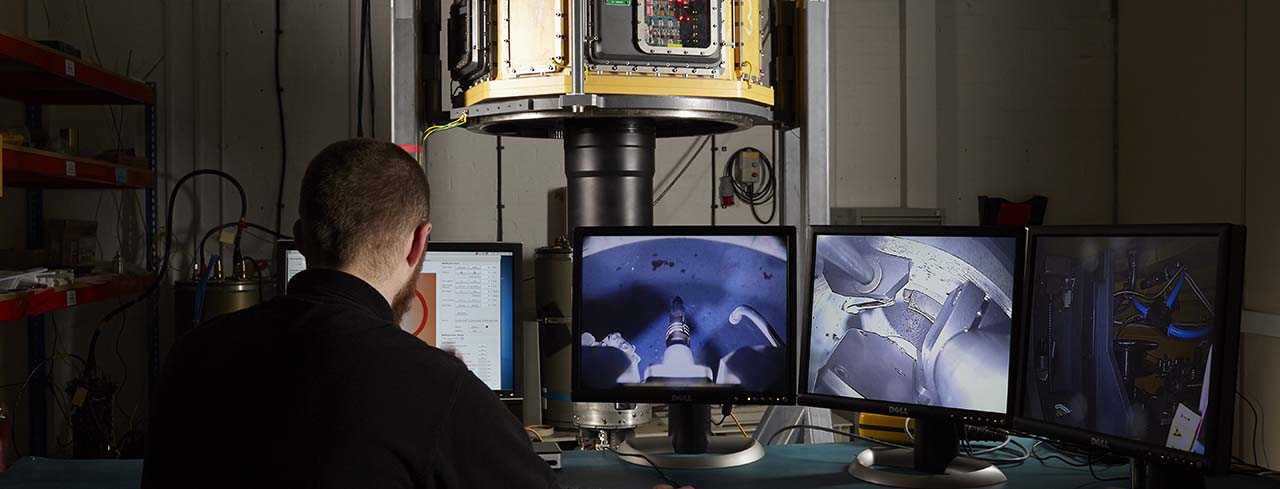

Welding Control

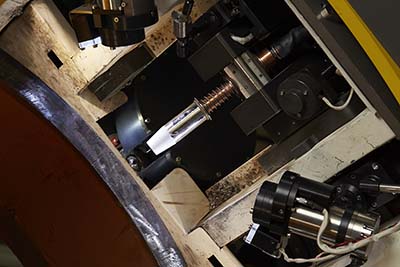

Isotek is the only company in the world with experience writing software for hyperbaric MIG and TIG welding control. This is the most elaborate control software we do – it has to be very precise and orchestrates a number of key operations including the position of the welding torch so it reacts dynamically to the surface being welded, the welding current and voltage and the wire feed speeds.

Our key areas of expertise include:

- Developing control systems ranging from single standalone units to large-scale distributed systems comprising tens or hundreds of interconnected controllers

- Bespoke software development that supports systems operating in extreme environments

- Writing software for precision control

- Using software components in new ways to resolve a range of issues

- Managing pluggable hardware with embedded software that makes components interchangeable without needing reprogramming

- Linux, Windows, and embedded software on a variety of platforms

- Over the years we have developed a library of version controlled recipes allowing us to track all components in each product we have made. This registry is invaluable when upgrades or repairs are necessary

- Real time fixes and experience gained from thousands of hours of real-time running can be rolled out offering an enhanced start to new projects.

Listing Details

Visits

756

Redirects

143

Don't Miss Out! Get the Best Deal on this Software - Email Us Now!