CirWarp

Overview

Circular gas charts have been in use for many decades in the natural gas production optimization and volume monitoring disciplines. There are multiple variants of gas charts with varying scale configuration depending on the manufacturer of the chart papers and recorders.

Previously, reading these gas charts would require either manual eye-balling on discreet points, or digitizing using a mechanical apparatus. These methods are exposed to many risks such as human error, mechanical calibration error, chart paper deformity / wear and others.

Geo-Zen introduces CirWarp, a circular chart digitizing service to quickly digitize and integrate circular gas charts of 12” diameter in size and below using an automated computer system. The output can be customized according to the customer’s objective according to a specified calculation method.

How It’s Done

Our integration process involves four main elements:

- Scanning

- Digitizing

- Analysis

- Output Delivery

Scanning

Our company has researched an optimum way to digitize circular charts for integration purpose. This step involves complex calibration steps that varies between different combinations of scanners, scan configuration and chart papers. Streamlining this process within our control enables us to offer synergized value at cheaper cost to the customer.

However, if our customer prefer to do the scanning step on their own, they are still welcome to use our service but this comes with an additional image processing surcharge (in order to standardize differences in scanned charts prior to our automated integration process). To ensure the highest level of service quality and output, we also will have to reject non-optimal images if these are passed to us by our customers.

Digitizing

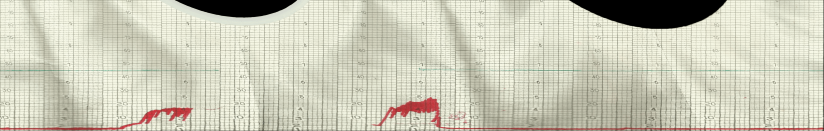

Using pre-defined calibration points specific to each gas chart type, we will run the scanned circular gas chart images through our software to extract chart values. We do this by initially warping the circular gas chart into a linear chart using our proprietary algorithm.

If the gas chart is of a new type that we have not worked on previously, we will consult and work together with the customer to confirm the curve-to-scale pairing and derive the correct calibration points. If this case, we will need some time to setup the calibration points and curve digitizing automation.