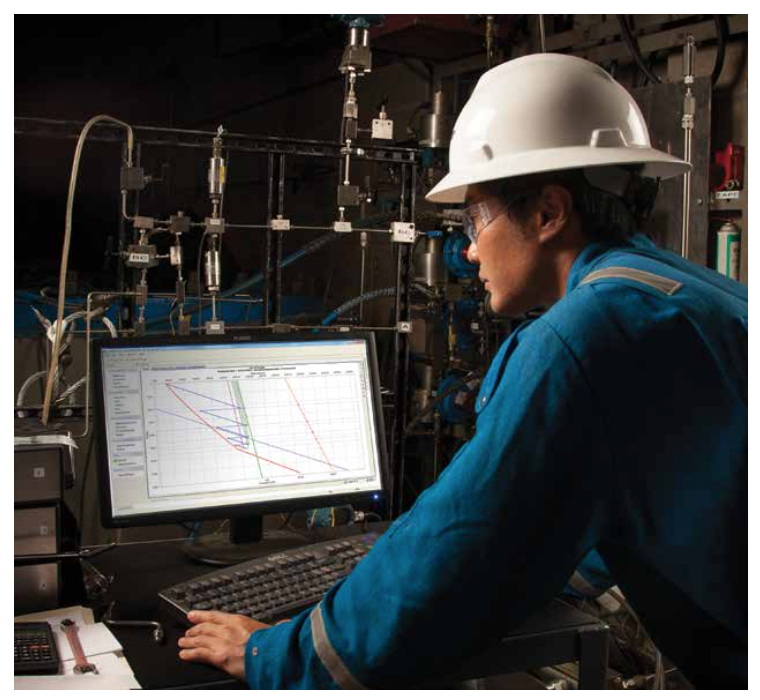

DesignRite

DesignRite* artificial lift design and optimization software is used daily by engineers across the globe. The user-friendly software helps determine the optimum ESP and gas lift system for individual wells. Users are guided through an intuitive workflow to carefully select each well system component from a comprehensive catalog of the latest lift technology and equipment. The software output is designed with the end user’s workflow as a driving parameter, and the result is a complete ESP or gas lift solution best-suited to maximize production and minimize downtime of an operation.

Reduced uncertainty of current and future well performance

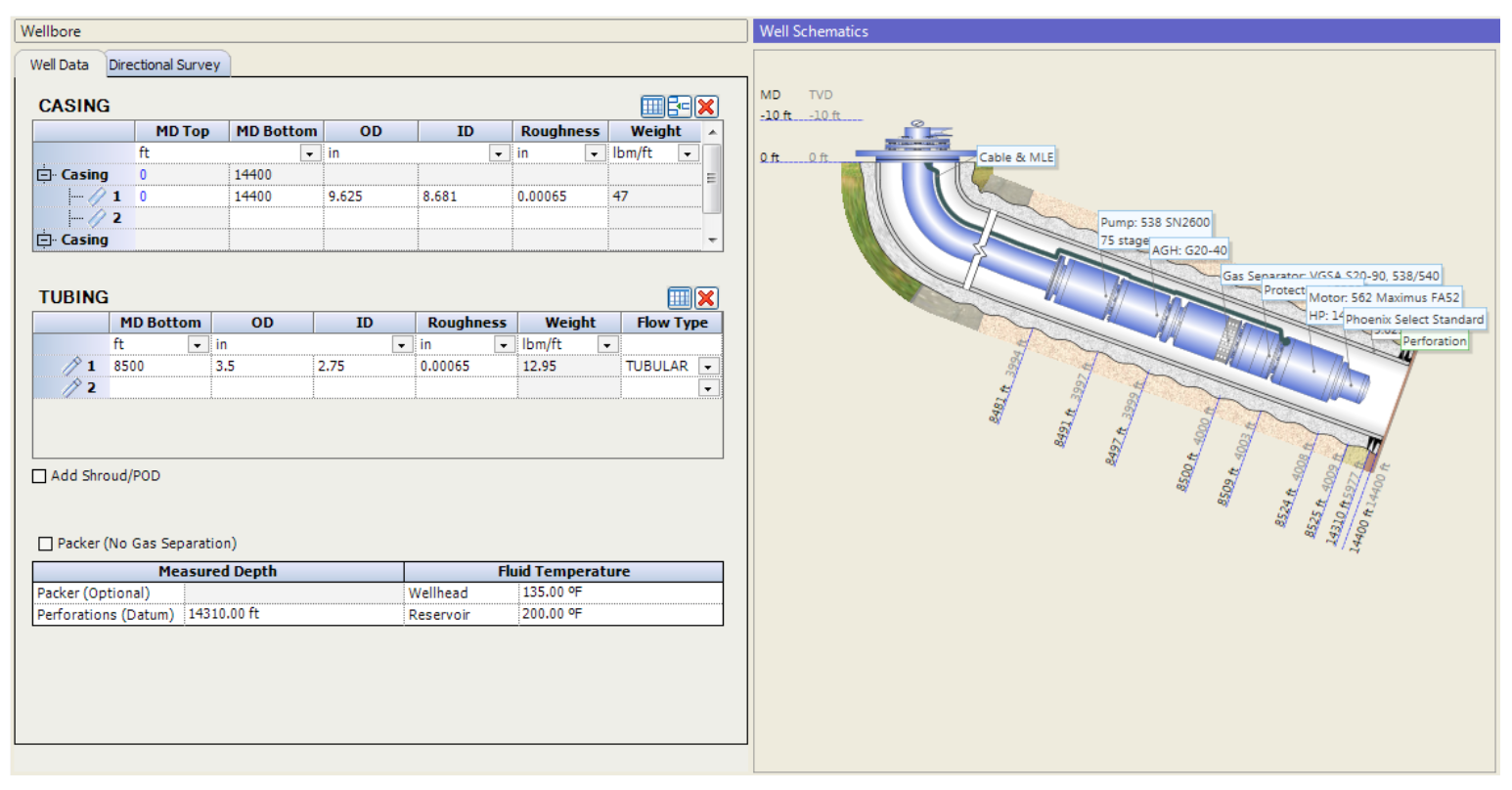

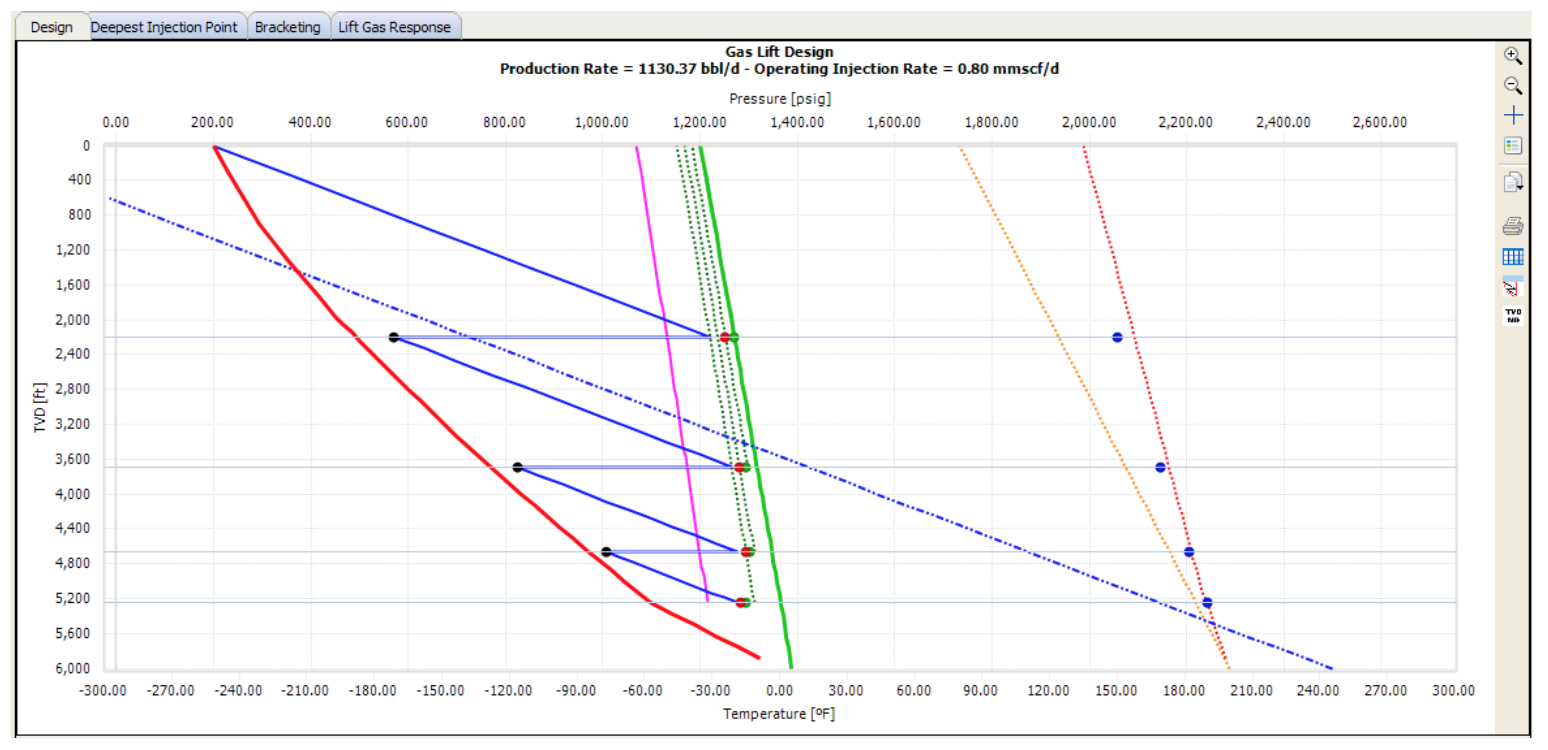

To ensure longest-possible operation in a well, accurate performance prediction of each system component at field conditions is crucial. While leading users through a step-by-step design process, DesignRite software sizes and analyzes entire ESP or gas lift systems and uses the inputted fluid, well, and reservoir information to predict the inflow and outflow performance of the systems. With extensive case-comparison capability, the software accounts for varying field and well conditions when helping engineers with the design and selection of the most effective lift system for their well.

Workflows for a wide range of applications

The ESP design mode incorporates methods and equipment for low-gas-oil ratio (GOR), high-GOR, and very-high-water-cut applications. The step-by-step data entry and selection simplifies the design procedure of the complete ESP system, which ultimately quickens the process and decreases production downtime. It allows pump selection based on the estimated pumping rate, calculates total dynamic head, and provides well conditions and casing size limitations. It also includes motors available in a broad range of voltage ratings with multiple cable, protector, ancillary equipment, and surface equipment selections.