DynaLift

Unloading is a critical point in building a gas-lifted well. A precisely designed uploading plan removes the kill fluid from the well to yield an optimally producing well. But a variety of factors—including port sizes, valve pressures, injection-gas availability, and changes in the formation can cause the well to unload improperly if at all, or worse, reduce your ultimately recovered reserves.

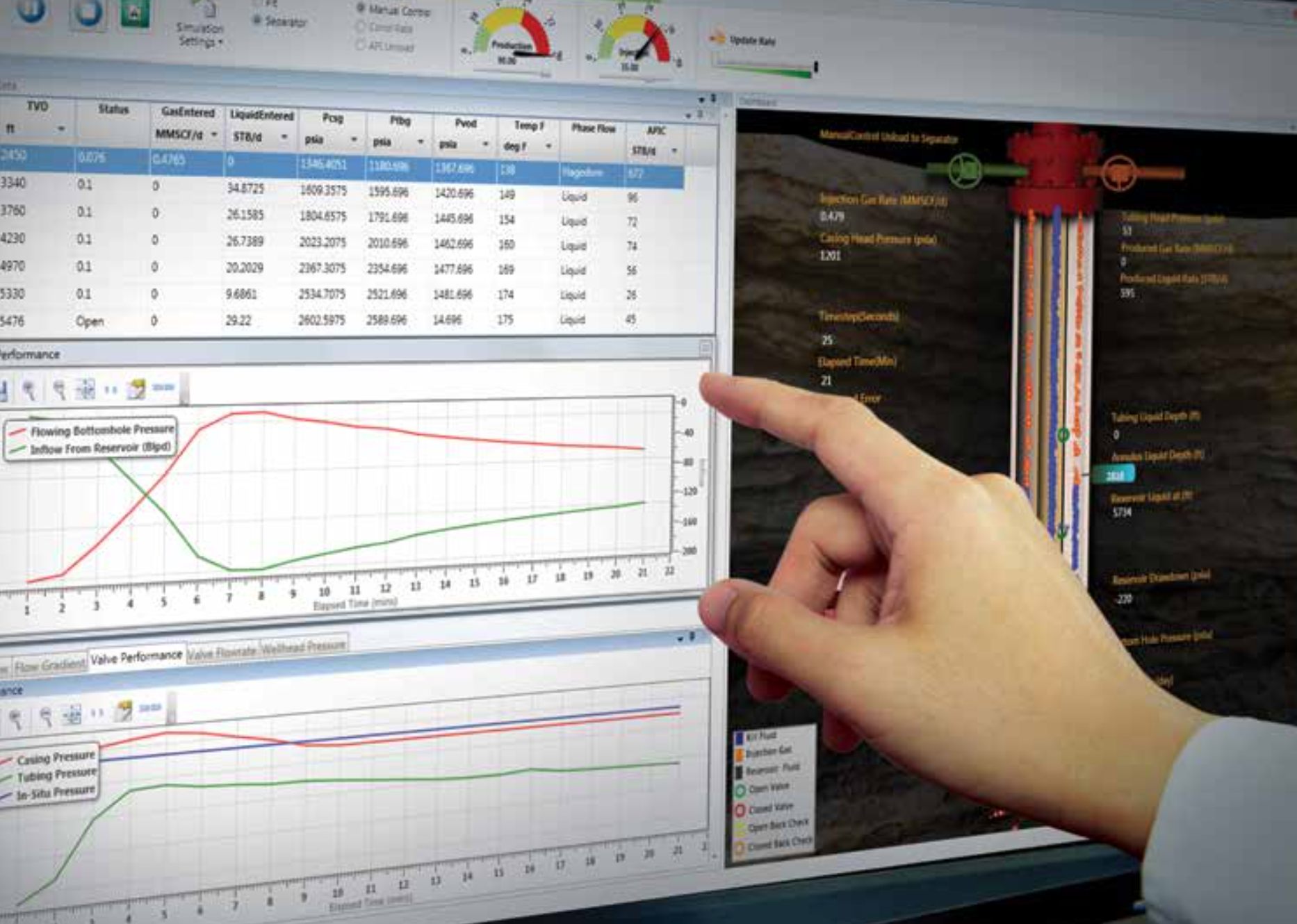

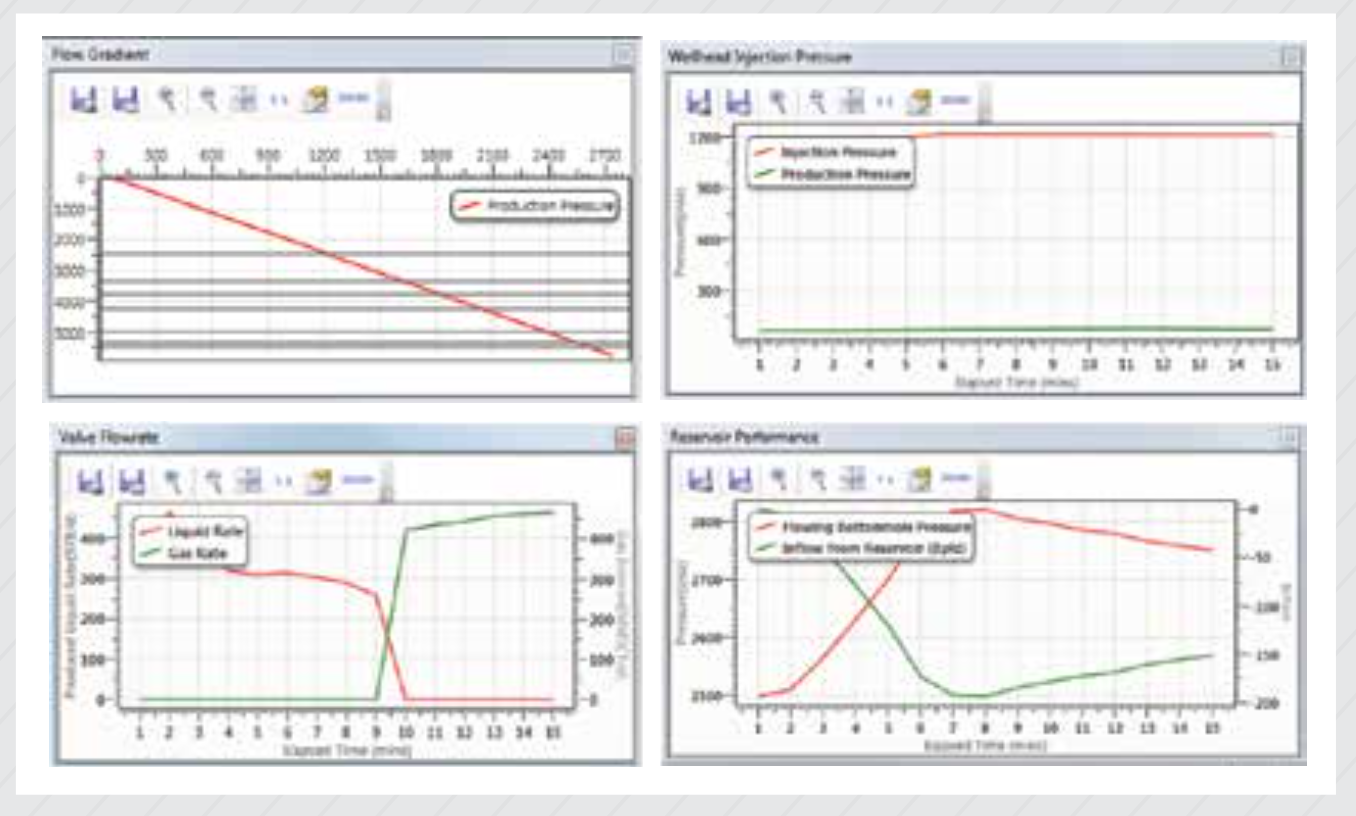

Our DynaLiftTM dynamic gas-lift simulation software empowers you to interactively test and fine-tune your design before your gas-lift system goes into the well. This unique tool provides a visual simulation of the dynamic gas-lift unloading process by modeling the transient flow from the wellbore through the reservoir. The simulation identifies design and operational issues from multipoint injection, injection through shallower valves, and unstable flow conditions.

The system enables you to mitigate the risks inherent to gas-lifted wells. DynaLift software not only helps determine whether the unloading process will be successful, it also provides critical details on valve performance by drawing from the integrated Valve Performance Clearinghouse (VPC).