TubeFlow PIC for Injection

Well Injection Software Suite

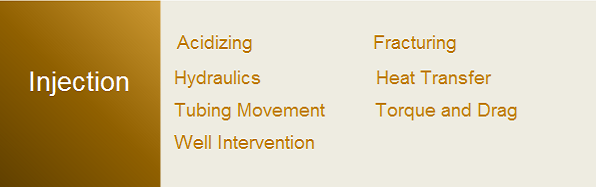

The software suite for well production in TubeFlow PIC is used to model production and injection operations.In addition, well intervention with coiled tubing, capillary string, and wireline can be simulated. Applications that are included in the well production software suite are listed below:

Acidizing

- simulates acidizing operations to aid in pre-job planning

- provides acidizing treatment recommendations

- supports coiled tubing acidizing jobs

- models wormhole penetration depth in carbonate acidizing

Fracturing

- supports conventional and multi-stage fracturing operations

- calculates pressure loss through restrictions and perforations

- estimates the fracture geometry using 2D fracture models

Hydraulics

- models production, injection, and circulation of fluids in the well including effects of heat transfer to/from the formation

- supports a wide spectrum of wellbore fluids ranging from single phase fluids such as air and brines to more complex multiphase fluid system (e.g. foams)

- multiphase flow modeling includes both empirical and mechanistic models

- supports injection of steam and sluries

- injection operations: formation fluid leakoff modeling (steady, transient)

- designs insulation/packer fluids for deep water environments with flow assurance problems

- supports real-time modeling

Torque and Drag

- considers three types of well intervention: coiled tubing, capillary string, and wireline

- evaluates forces and stress on coiled tubing, capillary string, and wireline during well intervention

- determines the buckling status of intervening tubing in the well and identifies lock-up/compression depth

- estimates the fluid drag on tool during well intervention

- calculates the set down wieght and overpull while run-in-hole (RIH) or pull-out-of-hole (POOH)

- models extended reach by determining minimum tractor pull requirements

Tubing Movement

- predicts the length and force changes in tubing due to piston, buckling, ballooning, and temperature effects

- determines the maximum triaxial tubing stress and aids in material selection for feild operating conditions

- considers effects of slackoff/pickup in tubing forces calculations

- includes fluid flow and formation heat transfer effects

- determines packer-to-tubing force and designs length of seals required

Benefits

- performs a comprehensive engineering pre-job design and post-job analysis

- reduces job design time and cost

- ensures pressure limits during a job are within safety standards

- optimizes a well intervention program and pump schedule for a job

Listing Details

Visits

1,391

Redirects

319

Don't Miss Out! Get the Best Deal on this Software - Email Us Now!

Map

© OpenStreetMap contributors