FloWax™

FloWax is a powerful multiphase pipeline simulator with wax deposition modelling capabilities for flow assurance and production applications.

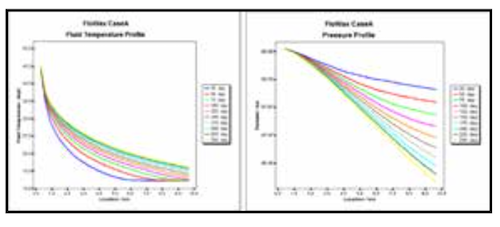

Through the unique blend of Multiflash’ advanced wax thermodynamics and a robust implementation of multiphase flows model in pipeline, FloWax allows Flow Assurance and Production engineers to predict the evolution profiles of:

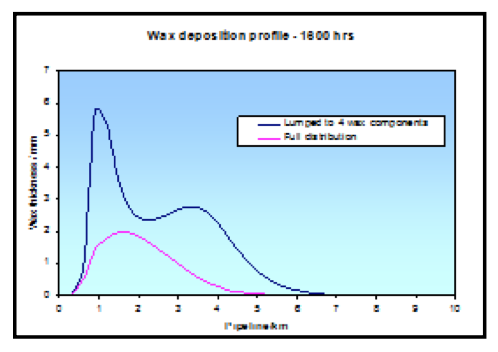

- the thickness and the physical properties of wax sediments along the pipeline

- pressure and temperature of the bulk fluid

- the physical properties (density, speed, molecular weight, viscosity, holdup ) of the gas,

- hydrocarbon liquid and aqueous phase

- Based on the predicted wax thickness profiles and the criteria required for wax

- management in production pipelines, the pigging frequency can easily be evaluated.

The built-in pipeline design tool allows including in the model, the pipelines’ geometry, building material, presence of thermal insulation as well the environment in which the pipeline is set. Temperature and Pressure profile from third parties simulators such as Olga can also be imported and matched.

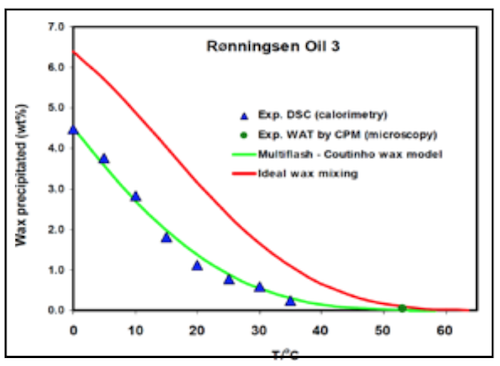

FloWax embeds Multiflash thermodynamic modelling and petroleum fluid characterisation capabilities, however, model files generated with Multiflash standalone can also be used to model the fluid and solve flash calculations.

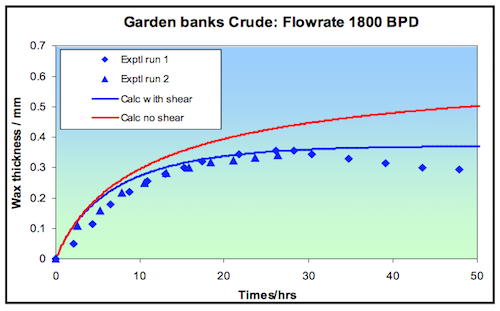

The multiphase flow model takes into account for different flow regimes as well as the heat transfer between the pipeline and the environment and models the deposition of wax along the pipeline walls, based on mass transfer method. The shear removal model developed with large flow-loop experimental data can also be included for highly turbulent regimes.

In FloWax the effect of entrained solid waxes on oil rheology is also taken into account to provide reliable predictions on oil viscosity. The model can handle the coexistence of wax sediment, hydrocarbon liquid, aqueous phase and gas. However, the number of phases actually present along the pipeline is determined by the full solution of the phase equilibrium calculation with the built-in Multiflash engine.