Multiflash™ Popular

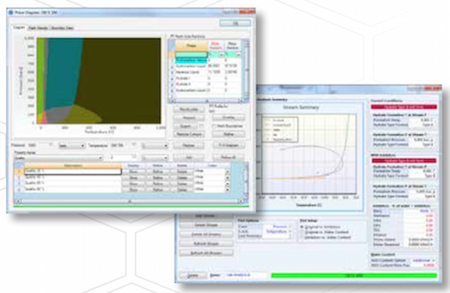

Our expertise in thermodynamics and physical properties and rich software suite enable reliable and accurate modelling of real fluids’ phase behaviour for reservoir samples, oil and gas production and processing, flow assurance applications and sizing of equipment and facilities.

The combination of KBC’s detailed engineering process simulation and energy management technologies with our capability and understanding of reservoir production and complex fluids behaviour provide a powerful set of engineering Flow Assurance Software and wax deposition solutions for asset owners, operators, oilfield service companies, EPC contractors and equipment manufacturers and integrators.

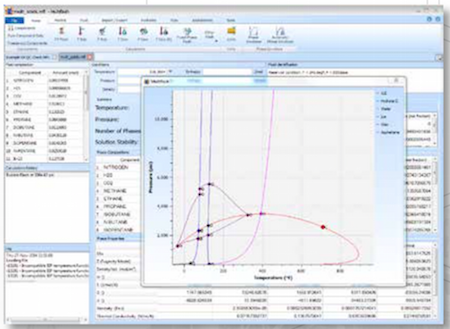

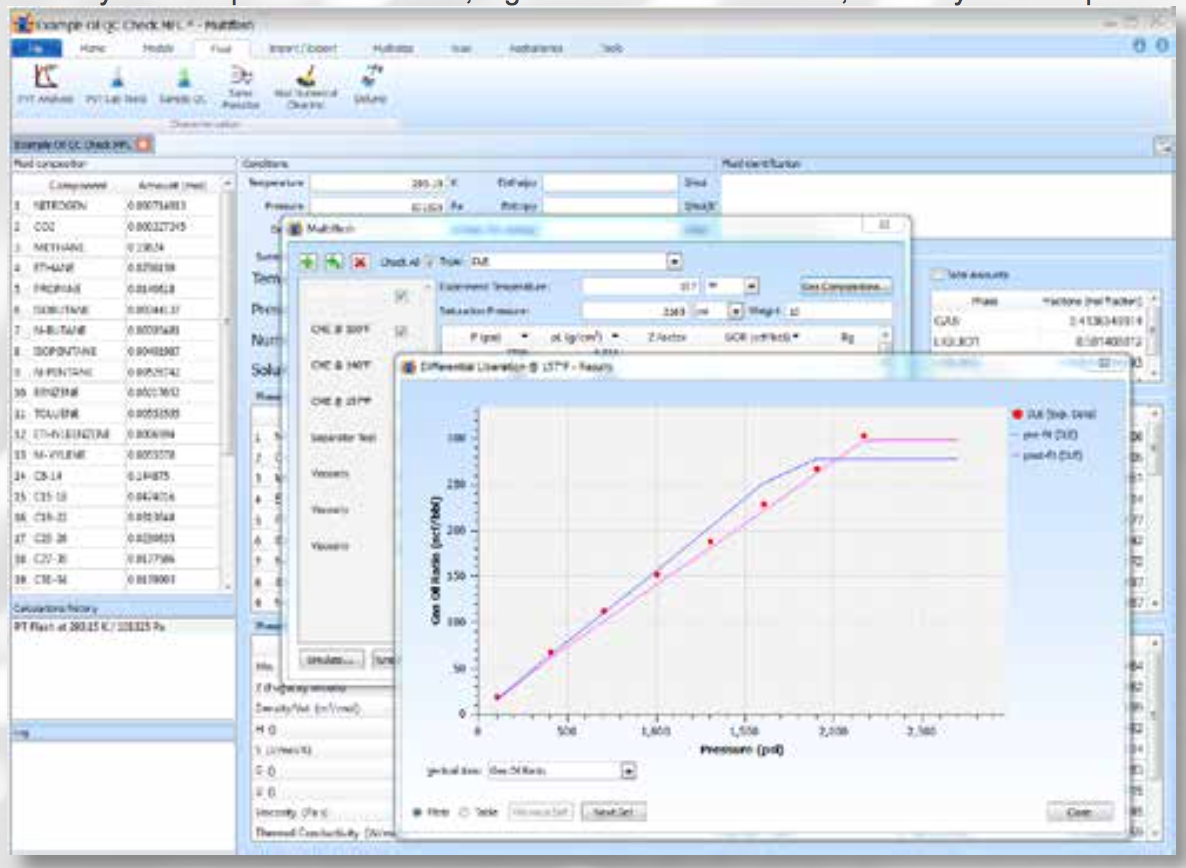

Multiflash provides a complete and reliable solution for the evaluation of the phase behaviour of complex fluids across the whole equipment and plant design process and during operations, and enables engineers with quantitative information and data to rapidly assess options, make informed choices and predict or prevent potential problems.

Either as a standalone, self-contained solution, or as the embedded PVT engine in leading process, flow assurance and production simulation software, Multiflash is accessible through multiple interfaces. Through its wide connectivity, Multiflash provides engineers with countless possibilities to customise and optimise their workflows, relying on a consistent, coherent and highly accurate fluid’s description including complex petroleum fluids, natural gas and condensates, Hydrates, Wax, Asphaltene, Mercury, Scales, acid gases, alcohols and glycols, polymer blends, chemicals, petrochemicals, refrigerants etc.

Through a wide range of thoroughly tested thermodynamics models, a database of more than 250 pure substances and a unique connectivity, Multiflash is the standard choice for Production Chemists and Flow Assurance, Production and Process Engineers, throughout the entire oil and gas value chain, from the reservoir to the refinery.