ALK-SIM™

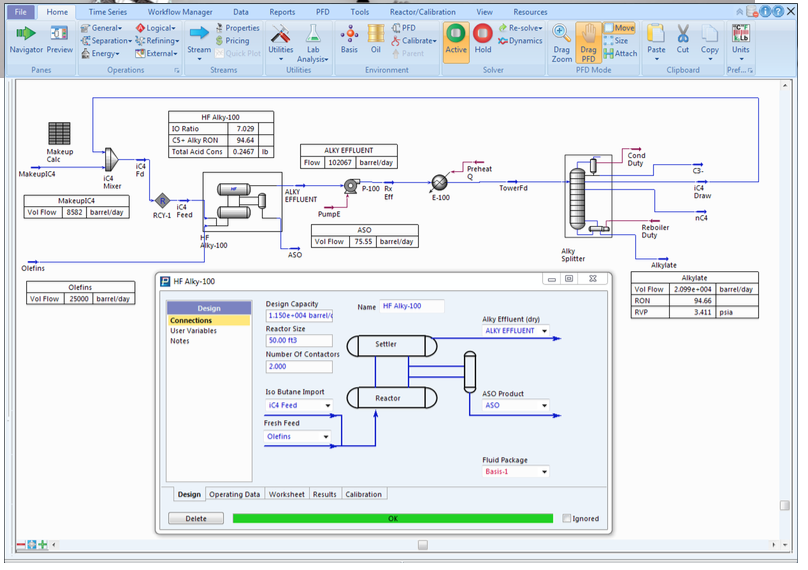

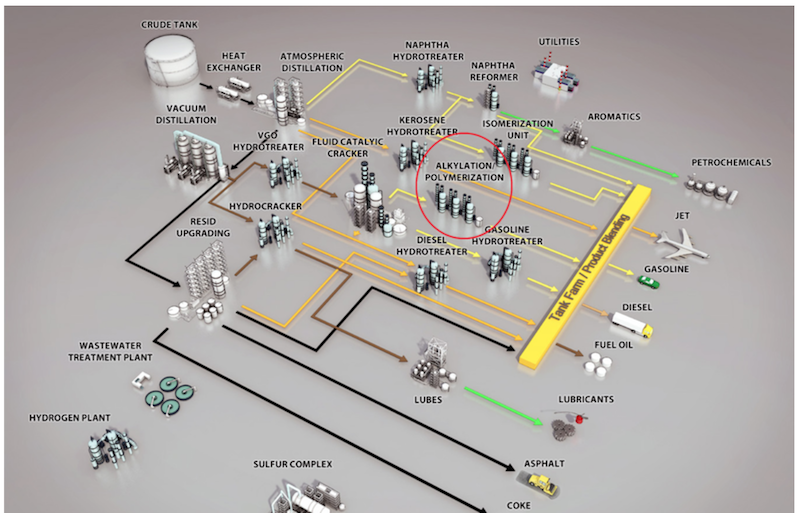

Alkylation is a key process that creates high-value products from intermediate refining streams. Use ALK-SIM, proven over decades of use within refineries worldwide, to evaluate alkylation of various C4 and C5 olefin isomer feeds under different scenarios of iC4/olefin ratio, reactor temperature and acid strength. For specified feeds, operating conditions, and constraints, the program determines resulting product flows and properties and overall unit operating economics.

Benefits:

- Selectoperatingtargetsby determining the effects of increasing the iC4/olefin ratio by changing recycle rate and the effects of changing reactor temperature

- Discovertheeffectofchanging acid strength

- Evaluatetheeconomiceffectsof recycling more iC4, increasing acid strength, or lowering reactor temperature and the economics of alternate reactor configurations Maintain the refinery LP

- Findoutwhatvectorsareneeded to model the incremental yields for different olefin feeds and operating conditions in the LP

- Allowsrapidregenerationofdata when model or LP structure changes Understand unit behaviour

- Understandtheeffectsofanew feed on alkylate product qualities and yields

- Evaluatetheyields/propertiesfor C3/C4/C5 olefin feeds

- Trainengineersandoperatorsnew to alkylation operations through a series of simulation runs to evaluate cause-and-effect results Monitor unit performance

- Trackmassbalanceandother key process indicators

- Compareactualyieldsversus predicted versus normalised

Listing Details

Visits

1,681

Redirects

301

Don't Miss Out! Get the Best Deal on this Software - Email Us Now!

Map

© OpenStreetMap contributors