DC-SIM™

Delayed coking is a key process used in many refineries to convert residual streams to more commercially viable products. Delayed cokers present numerous unique operational and safety challenges not faced in other process units. How do feedstock quality changes affect liquid product yields? Coke properties? Coke drum fill times? Coker furnace fouling and run lengths? From an operational perspective, what is the impact on product yields and qualities of changes in drum operating pressures? Temperatures? Recycles rates? Fractionator conditions? By allowing you to predict coker yields and product qualities for all your feedstock possibilities, coke drum operating conditions, and recycle rate options, DC-SIM enables you to answer these and many other important questions to enable you to operate this unit more effectively and safely.

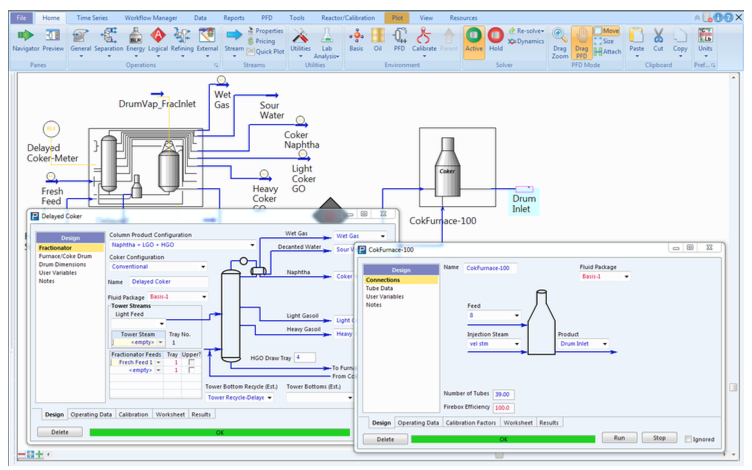

DC-SIM, proven through decades of use by refiners worldwide, allows you to model the impacts of a variety of different feedstocks such as atmospheric residuals, vacuum residuals, or FCC slurry. The simulation includes the furnace, drums, main fractionator, and the drum vapour quenching system. Cycle time (drum fill time) and resulting coke qualities are predicted.

Benefits:

- Determinethemostprofitable operation of the delayed coker given its constraints (heater, coke product properties, pump and compressor capacities)

- Generateaconsistentsetofyield vector that accurately reflects the feeds from different available crudes

- Regeneratedatawhenthemodelor the LP structure changes

- Determinetheyieldsforresidual feeds from different available crudes and the yield shift as increasing amounts of vacuum gas oil are removed in the vacuum tower

- Findthecokefilltimewithdifferent feeds, feed rates, drum temperatures, and recycle rates

- Trainengineersandoperatorsnew to delayed coking by using the model to illustrate cause and effect through simulation runs

- Trackmassbalance,furnacefouling, product yields and qualities, and other key process indicators

- Compare actual yields versus predicted