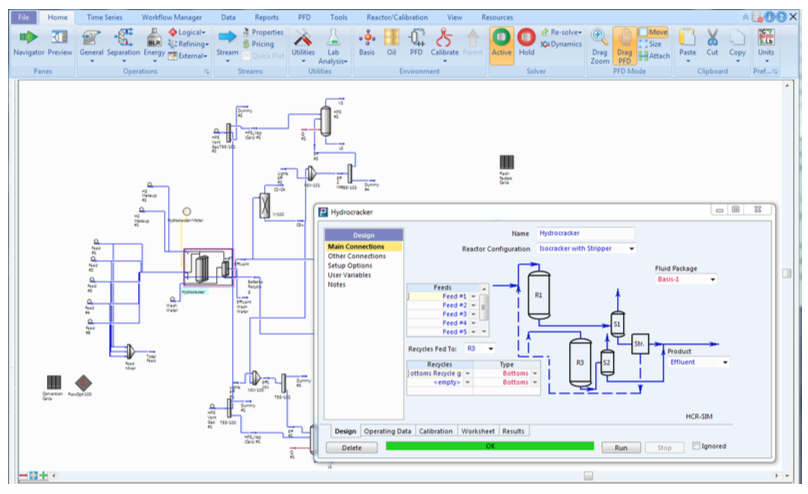

HCR-SIM™

Are you wondering what the optimum severity to run your hydrocracker is given changes in final product demands? Are you trying to balance severity against desired run lengths? Are you hydrogen constrained and need to understand the real hydrogen demands within your refinery? Are you trying to balance per pass conversion against total conversion?

KBC’s HCR-SIM has been used worldwide for over 20 years to help refiners just like you to answer these and many other questions. HCR-SIM lets you examine the effect changes in operating conditions, feed rates, feed qualities, severity (total and per pass conversions), and recycle cut point have on yields, hydrogen consumption, and catalyst run length.

HCR-SIM has been used successfully to:

- Generate and maintain LP vectors

- Analyse the impact of changes in feed and operating conditions on unit performance

- Optimise unit operation against real constraints

- Track and trend unit performance indicators

- Determine hydrogen demand for changing feedstocks

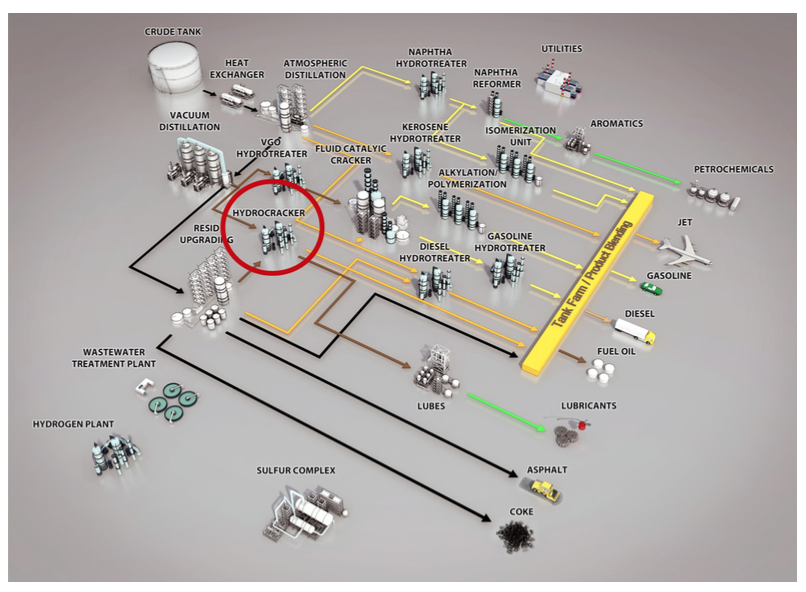

HCR-SIM can be used in standalone mode to investigate the performance of the hydrocracker unit in isolation, in conjunction with FCC-SIM, KBC’s fluidised catalytic cracker model, to investigate the tradeoffs between the operation of these two units in conjunction with each other, or as part of a refinery wide model that investigates the complex relationships between different processing units and the macro effect of changes in the hydrocracker unit on the entire refinery performance.