REF-SIM™

Are you trying to maximise hydrogen production? Optimise gasoline blending against stringent sulphur and benzene specifications? Are you concerned with minimising yield loss across your reformer? Do you need to maximise aromatics production for downstream petrochemical processes? Are you concerned with catalyst life and trying to optimise the run length?

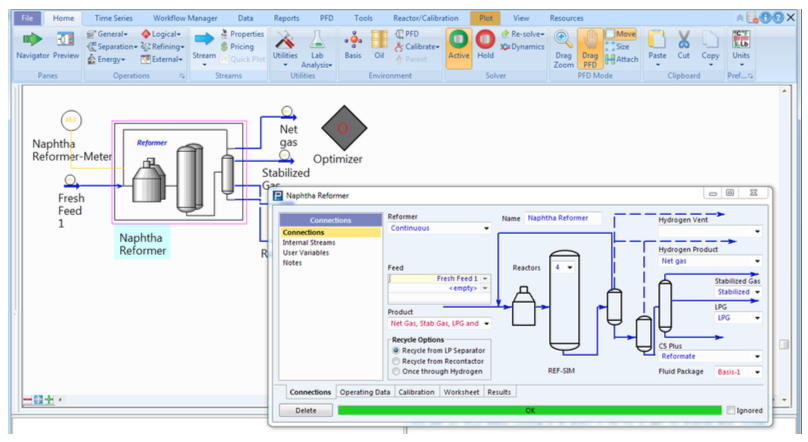

KBC’s kinetic catalytic reforming model Ref-SIM has been used worldwide for over 20 years to help refiners just like you to answer these and many other questions. Ref-SIM enables you to examine the effect of changes in feed rate and composition, operating severity, and recycle hydrogen quality and quantity on yields, product qualities, and catalyst run length.

Ref-SIM has been used successfully to:

- Generate and maintain LP vectors

- Analyse the impact of process changes on performance

- Optimise unit operation against real constraints

- Track and trend unit performance

- Determine hydrogen yield for changing feedstocks

- Monitor catalyst deactivation

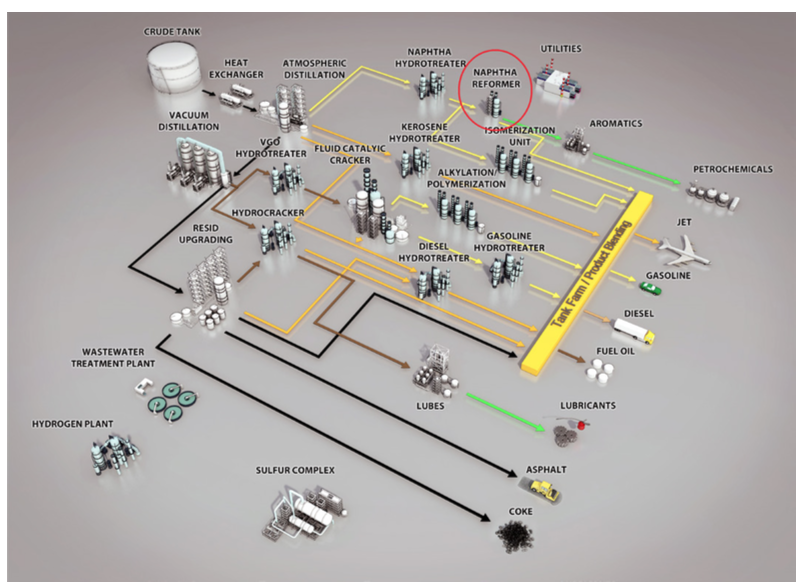

Ref-SIM can be used in standalone mode to investigate the performance of the catalytic reforming unit in isolation, as part of a hydrogen management study with other hydrogen producing or consuming units, or as part of a refinery wide model that investigates the complex relationships between different processing units and the macro effect of changes in the reformer unit on the entire refinery performance and final product blending.