VMGSim Dynamics Popular

VMGSim Dynamics provides world class dynamic features and user friendliness in a unified life cycle environment, while reducing software costs and making dynamic simulation affordable to companies in the process industries.

Improve your process performance in a unified environment

The process industries are dynamic by nature, rarely operating at steady state. Changes in feed flows and compositions, external disturbances and changing equipment performance continually effect the process operation.

Use VMGSim Dynamics to:

- Simulate process operability during upsets

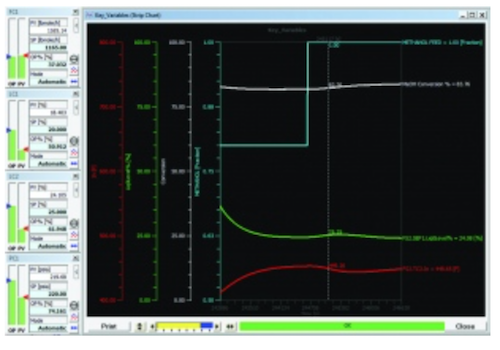

- Evaluate process equipment, and control strategies

- Develop start up, shutdown, and operating procedures

- Perform regulatory control system studies

- Perform step testing off-line

- Perform rigorous blowdown/depressuring

- Evaluate relief loads from causes such as reflux pump failure, fire, and power failure

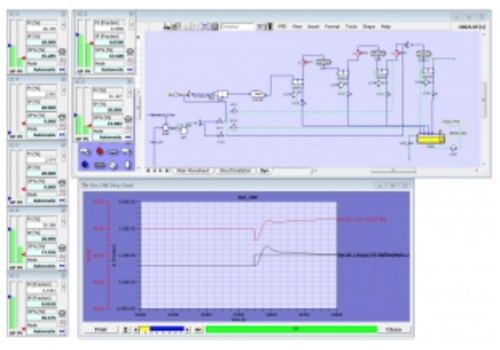

A VMGSim Dynamics model incorporates equipment information, a control layer, and provides a complete, offline virtual plant.

The model enables an engineer to gain process understanding and evaluate changes made that can improve performance of the process.

Benefits of Dynamic Simulation

- Dynamic modelling of the process developed in the design phase can highlight changes in the process configuration and equipment sizes that reduce equipment capital costs

- Industry experience has shown that the same model can reduce start up times by as much as 70%

- Reduce APC implementation costs by as much as 30%

- Provides relief scenarios a more accurate analysis of relief loads, saving millions of dollars on flare system revamps