Drilling & Completion Software

Drilling & Completion Engineers in oil and gas industry are responsible to drill a well and making a well ready for production and injection. This basically means once drilling is finished, downhole equipments (e.g., casing, cementing, perforating, gravel packing, linear, valves, production string) need to be installed. Perforating and stimulating production/injection well is also part of completion process.

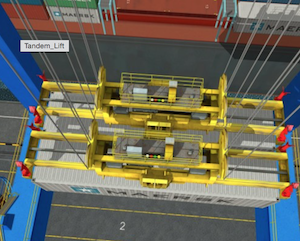

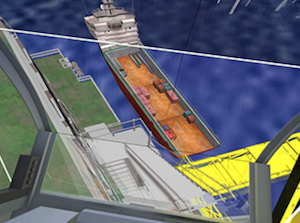

Unique customized training possibilities hiCRANE Port simulators provide high quality 3D visualization of a synthesized virtual container or bulk terminal. In the full-scale simulators, the crane operator is seated in a cabin fully surrounded by an interactive world, which can be easily populated an ...

Read More ...

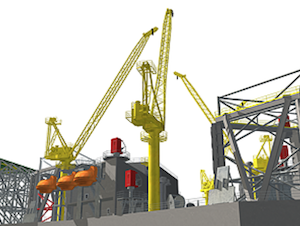

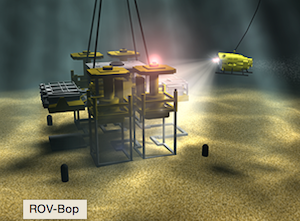

Simulator training environment hiCRANE Offshore simulators provide high quality 3D visualization of a synthesized virtual offshore platform environment. In the full-scale simulators, the crane operator is seated in a cabin fully surrounded by an interactive world, which can be easily populated and c ...

Read More ...

Strong of its expertise in the interpretation of combined down-hole and surface drilling data, Epslog has developed DREAM, a powerful software that regroup efficient algorithms, scientific techniques and visualization tools to extract valuable learning out of complex interpretation of drilling data. ...

Read More ...

The Industry Challenge: Various mechanisms can cause deformations of a well casing that can inhibit well access and in severe circumstances, affect the pressure integrity of the casing and the zonal isolation of the well cement. Deformation mechanisms can include salt creep, reservoir compaction, mo ...

Read More ...

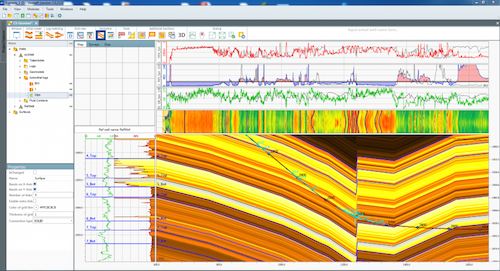

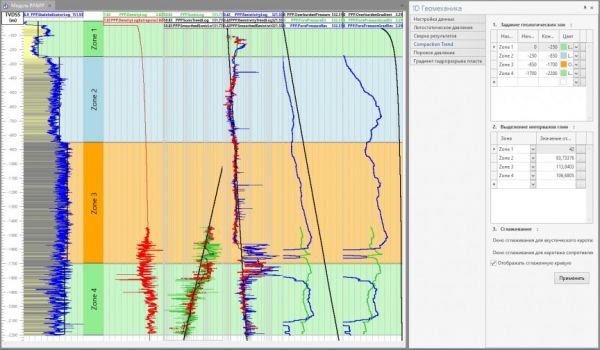

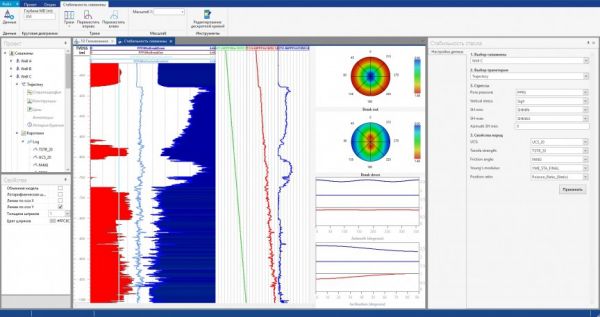

“Geonaft” is a modular software package intended for comprehensive engineering support for directional and horizontal wells drilling aimed at the most successful bore positioning in a target horizon.

SP “Geonaft” allows determining the well stratigraphic position while drilling as well as to foreca ...

Read More ...

DrillScene is an advanced software tool for monitoring and trend analysis during drilling operations. It creates a dynamic, real-time picture of the entire wellbore with changes between the model and reality visualized as trends graphs. This helps drilling analysts and engineers to optimize operatio ...

Read More ...

DrillTronics software automates drilling process control, enabling drillers to optimize and enhance the safety of their drilling operations. Integrated with the rig’s drilling control system (DCS) machine controls for drawworks, top drive, and mud pumps, DrillTronics applies the same advanced modeli ...

Read More ...

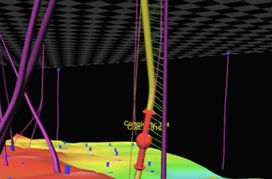

Higher productivity and lower costs through informed decision making while drilling. With Paradigm® OpsLink®, operating companies’ asset teams can make rapid and informed critical decisions while drilling based on real-time data, in order to avoid drilling surprises and optimize well position in the ...

Read More ...

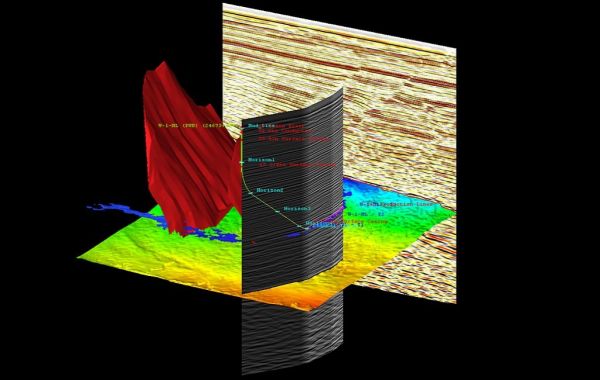

An integrated, contractor-independent solution. The Paradigm® Sysdrill® integrated suite of well planning and drilling software solutions helps operating and drilling service companies enhance well planning accuracy, reduce drilling risk and uncertainty, quantify wellbore position and precision, and ...

Read More ...

Integrate multi-disciplinary data including geologic, geophysical, cultural, and production data with 3-D visualization and 3-D interaction. Take advantage of unique well path planning optimization algorithms to educe errors and oversights in the planning process. Reduce cycle time. Dramatically red ...

Read More ...